I have had a glazed entry door and sidelight installed in my current build. They are from a well known National company. They are made from water resistant MDF and have routing around the glass panels, and beading on one side only. All states except QLD recommend they be installed with the beading external or warranty is voided. My build is in Northern NSW and have the beading internal. I was told by staff at my local hardware, and by a local building supply store that the beading should be external or I will have issues with water ingress and swelling. I met with the company Rep (from QLD) who stated the beading should be internal but could not give me a reason why. I emailed the Sydney Head Office (twice) and received no response. I did get a call from the QLD Sales Manager who said that “the internal beading suits the QLD climate better” but could/would not give any reason why. The door needs repairs already as one of the glass panels has a 4mm gap at the front. Other national door companies mention having the beading exterior. Does anyone have a clue about what is the correct way to install as I am not trusting that I won’t have an issue once I move in.

Greetings @MKen22. Could you give us the name of the supplier and the product so that we can have a look at the documentation, warranty and the design.

The door and sidelight are from Hume doors - Newington XN5 and XN11 in paint grade.

Is that a reference to the supplier/manufacturer or a building code?

I’ve recently purchased in QLD from a noted manufacturer two new external facing and glazed doors in Surian cedar timber. They came handed rebated for mortise locks, with the beading on the outward facing side. Two previous new builds we have occupied in QLD also had external beading on the entry door glazing. All have been well weather protected by entry overhanging porticos or roofing.

We have not had issues with timber shrinkage or gaps appearing around the glazing. Incorrect storage, handling, surface protection, or weather/moisture exposure can cause problems with any new door.

Note Hume’s advise minimum weather protection for entry doors and installation/protection requirements in their product for warranty.

‘https://www.humedoors.com.au/assets/5598

Manufacturers. The door/sidelight I have were manufactured in their QLD factory. The same door manufactured in other states have the opposite installation requirements. If my door had shipped from Sydney, for example, it would have a sticker on it stating to install with the beading exterior.

I also have plenty of coverage for the door as I extended the portico from the original plan size.

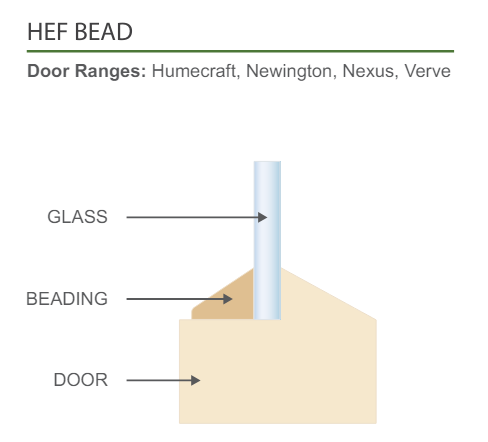

Looking at the Hume website, the Newington doors come with different beading options:

https://www.humedoors.com.au/assets/5526

The options appear cosmetic rather than for a particular installation/climatic environment. There isn’t any information I can find that states particular beading to be used in particular applications.

Where did you get the information on the reasons for the difference. If it was the seller/supplier/builder, I wouldn’t particularly trust them unless they had written information from Hume.

It may be that the Qld factory only does some beading types and not all. This often can occur with building materials as it can take time and cost to retool/setup for doing every option. If another factory can do some, while others fill the gap can make good business sense.

Hume will specify the side of the door which is exterior as this side will be designed to take the weather.

I cannot find any technical detail regarding your door that specifies installation methods or any warranty for it online, so that is no help. {edit} There is a guarantee but it doesn’t mention which way to hang a glass panel door.

I take it the door was installed fairly recently. I would be going to the vendor and getting them to deal with your problems. The two issues that I see are the way the door faces and the 4mm gap.

You have not had any joy so far on the first, however the vendor ought to attend to the 4mm gap by either repairing or replacing it. Under consumer law it is their problem not the manufacturer’s. Once you have their attention I would ask them to tell you in writing that the installation is in accordance with manufacturer’s requirements and the door is under warranty.

I cannot comment on the particular door. If I was installing a door with glass panels I would put the bead on the inside as it has two joins (one between the glass and the bead the other between the door and the bead) that need to be water tight and so it needs better protection from the elements than the other side where there is only one join between the glass and door. Why this would be any different in another state escapes me - and apparently everyone else too.

Humes product. Hopefully you have that officially in writing. As others have noted it’s actually the builder who is responsible to you.

Re which way the beading should face, I can’t find one clear answer other than to look at what I know from first hand. Following is a link to a pic of a new door produced by The Woodworkers. It’s a Brisbane QLD specific design. The beading is evident. The ledge faces the exterior as does the beading on the glazing. I’ve an original 1930’s version with exactly the same construction if there are any doubts about any change in practice.

‘Ashgrove entry door (loose) - Woodworkers XS

The Woodworkers also supply in NSW. I’ve not noted any comment on their web resources to suggest any difference between NSW and QLD in requirements.

One explanation for external facing beading is that fitting the glazing with the rebate on the inside provides a better weather seal. Any external water build up cannot flow under the edge of the glass through to the inside. To note weather sealing of the glazing used to rely on linseed oil putty. Not perfect over time. Most lower standard glazed doors and timber framed windows back in time used a putty seal (no beading) on the outside. Formed as a bevel to shed water. The glazing would have been held in place with small brads or pointed flat pins. Hence the logic of having the glass rebate into the frame from the outside for better resistance to water penetration.

With modern silicon or synthetic rubber based sealing loss of water protection is less likely a concern which ever way the bead faces. To note some (Google is referring one to UK sites) suggest external beading makes it easier to break in through a glazed door. Possibly true assuming a patient intruder, and less so if the door has an effective dead lock.

I thought I should add some further info regarding this door installation.

Prior to my build commencing, I believed the door to have the beading either external or both sides as all images I saw online showed exterior beading. Even the Hume website.

Here is a close up from their website

I visited a Bunnings store in Northern NSW prior to selection and saw the beading was only on one side. I asked a staff member which side is the exterior and was told the beading side. I could not see a sticker on the door but at the time was not looking for one.

After installation I was onsite and saw the undercoated door and sidelight and noticed the beading was internal. The exterior finish looked terrible and there were gaps in two panes (not one as I mentioned above). Here are some pics of the exterior.

I contacted my builder who said they had installed as per the Hume Standard. I was asked if I would like to be contacted by the Hume rep (QLD), I agreed and I met with him onsite.

Prior to the meeting I rang Hume Doors in Sydney, South Australia and Western Australia. All (after checking) confirmed the beading should be on the exterior. They each mentioned that the beading is primed for the exterior side, and said the sticker on the glass should state this.

I also rang the Queensland Office and was told that the beading can go either side.

I checked Bunnings again and found a Hume Newington door with a sticker recommending internal beading, and a Hume Joinery door with a sticker recommending the opposite

When I arrived for the meeting with the Hume rep onsite he was measuring the front door. I approached and introduced myself and he began by showing me that the gap between the glass and door frame was indeed too large and would need to be repaired. I then dared to ask him which side the beading should be on, and it all went downhill. The guy was beyond rude and was impossible to talk with. He constantly interrupted me, spoke over the top of me, and turned his back on me when I did attempt to speak.

I tried to inform him that I had spoken with staff at the different offices and they had said that the beading should be external but he interrupted with “wrong”. I said staff at Bunnings and a local Hume Door Building Supplier had said the same thing to again be told loudly they were wrong. I tried mentioning that I even asked on their Facebook page and was told the beading is external. He loudly again said they are all wrong.

He said in QLD they manufacture the doors to have the beading on the interior. I said my build is in NSW and he turned his back on me.

He texted me the number for the QLD Manager and said I should call him. I did and he told me he has worked there for 25 years and that’s how they do things. He said he would look into it and get back to me.

Last Monday I sent an email to the Sydney Head office. Six minutes later I received a call from the QLD Manager I had spoken to. He said they used to have the beading exterior but changed it as it better suited the QLD climate. His only reasoning was that there was a better seal this way. I mentioned my door has several large gaps and he said he would send me information to support his stance.

He sent an image of the stickers that state the door should be hung with the beading internal.

I resent my complaint to the Sydney Head office on Thursday, which has a different email address to the QLD office, and again received no response except another phone call (went to voicemail) from the QLD sales Manager. I have not spoken with him again but will call him on Monday.

I just don’t understand why all states have one rule except QLD. The same door is manufactured in the same way in other states, and in climates that are the same or similar to QLD, but have different installation recommendations.

Maybe I am being pedantic about this but it irks me and I don’t want to have to spend money down the track replacing a door and sidelight. I expected the door to look like it does in their advertising (exterior beading) and dislike it how it has been installed as per the QLD instructions. The finish looks like crap.

I understand it should be my builder who sorts this out, but they are just installing to the QLD manufacturers recommendation so as not to void the warranty. The warranty documents themselves do not include any statement regarding beading and installation of this door.

The sticker placed on the glazing after manufacturing is in QLD is the only statement on how the door should be installed as per beading, and this is the opposite to every other state except the NT (under the umbrella of Hume QLD).

That does not explain the gaps or the poor paint job. The gaps are probably not the builder’s fault but they are responsible for making a claim on the maker if it is a manufacturing fault. Leaving a gap like that will hold water and ensure the door rots in time. The point of having the glass set against a bevelled edge like that is to shed water not collect it. Is there any sealant hiding in the gap?

The painting is slap-dash, it would have taken little effort to mask the glass pane and prevent the mess.

Where one is not satisfied with the workmanship or door as installed.

The contract between yourself and the builder will advise on how to proceed if the builder does not accept your observations or respond to your needs.

If the builder is not in agreement, the best reliable advice on the condition and installation of the door will come from a registered professional. IE independent third party inspector. Most will for a fee (best to discuss and agree in advance) inspect the work and provide a written report. I’ve previously looked to those who provide certification or contract of sale building inspections. The builder does have obligations to complete the property to an acceptable standard. It’s important as the owner if there is an unresolved disagreement to follow the procedure set out by the contract. Some builders are adept at subverting complaints because the owner has not understood fully how to raise a dispute that will be legally accepted.

It may also help to resolve your doubts re the orientation of the door and beading. To note your observation it’s a Hume Doors requirement and not a building regulation that is being disputed.

P.S.

The close up of the paintwork hints at a further underlying issue. It’s impossible to say on the basis of the pics. Excess moisture or water exposure on site and prior to final painting is one common cause of problems with new doors.

The photo taken shows the bevel on the inside, not beading. Beading is a strip which is fixed to the window instead of glazing, to hold the window in position. Beading is shown on the Hume link provided in a previous post.

The photo shows a bevel which is the door material machined with a slope on it. It is machines door material as it is obvious that it is MDF as MDF tends to fluff up a little when machined to give the finish when painted as shown in the photo.

You may be confusing those you are talking to if you are using the term beading when it is the bevel you are referring to. I can’t see the external finish of the door to see if the beading is on the other side. I suspect that it may be as the inside doesn’t show a bead. If both side are bevels, the glass has been sandwiched between layers in the door manufacture.

You are also getting hung up on the position of the bevel. As you have had a Hume rep out who says it is okay, then it is okay.

The quality of the door is questionable and needs to be addressed, It looks like the glass panel wasn’t fully seated in the recess, thus causing a gap between the top of the bevel and the glass. If this was on the outside, it will cause swelling/rotting in the corner over time. As it is on the inside, it will be more cosmetic, however, if the glass hasn’t been seated properly, there could be additional gaps where water may intrude over time, causing premature swelling/rotting.

As the Hume rep/builder has indicated it is unsatisfactory, wait until the repair/replacement is done to see how it is. If it is then unsatisfactory, then see what avenues may exist to take it further.

The door has been installed with the bevel on the exterior. That is why I have issue.

That is standard practice for single glazed windows with the bevel on the exterior. The bevel is on the exterior to ensure that water is shed from the contact point between the door and glass, to ensure that water does not pool causing damage to the timber frame. It is worth looking at a glazed window as it will show the bevel (made from glazing putty) on the exterior of the window.

With a fixed bevel like that shown on the door, usually a sealant is placed between the glass and the timber frame to ensure that water can’t enter any gaps. Looking at the second photo, it appears that sealant has been used as it appears to be bulging from the gap near the corner.

If the 4mm gap is on the exterior, this needs to be fixed as it will cause premature weathering/damage to the corner.

As you have been calling the bevel a bead, this will have caused confusion with those you have been taking to. A bead is different to a bevel.

I have not been calling the bevel a bead. I fully understand the difference between the two, and never in my post or comments have I confused the two.

If you have a look at the image of the door from Hume’s website, the beading is clearly seen. Their state offices have told me the door (which has beading one side, routed edge the other) should be installed with the beading exterior.

Mine has been installed with the beading interior. That is my issue.

Do you have a photo of the finish on the exterior or is that the photo above? If it is the exterior, can you post a photo of the interior?

I think I am getting confused.

Beading can be installed on the exterior as well. Modern joinery often uses beading instead of glazing putty as it is quicker and easier to install. Many moulding businesses make beading for use for exterior applications. If timber beading is used on the exterior, it also needs to have sealant used between the glass and the bead to ensure that it is sealed.

There are beading which are only for internal use (refer to my previous post which has an example). Not knowing the material used in question, whether it is an internal or external beading etc makes it difficult to provide advice. As the Hume rep has said it is okay, it will be okay.

I personally would prefer an exterior timber beading on the exterior to machined MDF. While machined MDF may be suitable for exterior applications, machining it ruffles up the fibres making it easier for water penetration, especially if not sealed properly.

The door was installed without any sealing for at least a several days, if not a few weeks, as I met with the Site Supervisor after installation (for another matter) and noted it had been installed. It was at least a week later that I saw it had been undercoated.

Hume doors require all doors be sealed asap and this clearly was not done. I’m guessing you are referring to the “fluffiing” of the MDF? That is part of why I am concerned about the door. The rough edges cannot be easily sanded away prior to the final paint coats as it would expose unsealed MDF, which would then have fewer coats of paint and poor protection from the elements. Having the beading exterior may offer an extra level of protection from the elements as long the glazed panes are properly sealed.

If it was as easy as replacing the door down the track I would not be as bothered, but I am having the matching sidelight installed so any future changes will be more costly. Both the Hume rep, the Hume Sales Manager and my builder have also stated that the sidelight cannot be removed without having to remove the frame. A whole other issue.

Do you have anything written from Hume. It may be the case for doors which are exposed to or likely to be exposed to the weather. It is standard recommendation for some timber products to seal as soon as practicable. This generally means before weather/water/humid air has been allowed to affect the material.

An example being Gyrock. Gyprock is another material where it is recommended to seal as soon as practicable. In new home builds, the time between installing Gyprock and painting can be many weeks (until the painter is on site)…but leaving it exposed doesn’t impact on the quality of the material. If raw Gyprock was in a bathroom renovation, haste to seal would be important especially before its use.

Yes. MDF fluffs up a bit when machined. It is difficult to get a smooth surface sanding the raw (unsealed) MDF. A mate who used to be a cabinet maker said to paint with undercoat, then sand. The undercoat holds the fluff fibres allowing a smooth finish to be created. If they sand the door before the final coats, the MDF should be sealed. If they aren’t sanded off, over time, this can cause premature weathering. Not only premature weathering, but dirt, grime and dust settles in the rough surface making it extremely difficult to clean.

I would be ensuring that the machined MDF surface is treated to remove the ‘fluff’. It can be easily done.

The 4mm gap is the concerning issue as it will lead to water sitting in the gap - causing premature failure. From what you have posted, this is to be rectified.

This is the door exterior as installed. I do not have images of the interior as I met with the rep without my SS so did not have access to the interior. I have included an image from Hume which shows the glazing construction.

The beading they do use is primed timber (unsure what species but would expect a hardwood). It is nailed to the door frame and sealed with silicone between the beading and the glass. Aesthetically, I prefer the look of the beading side to the exterior, and this is how all images are shown online including in the Hume Facebook group and on their website.

Functionally, I understand a properly sealed bevelled edge would allow runoff and reduce the standing time of water adjacent to the glass pane. However, this door has an MDF core that clearly has a very rough finish on the bevelled edge after undercoating. Proper runoff is dependant on a smooth finish. If the edge is rough it will trap moisture and greatly increase standing time leading to rotting over time. If the painter sands the routed edges around the glass on my door to a smooth finish, which is difficult with MDF as it is like sanding cardboard and has no grain, the bevelled edges will have freshly exposed MDF. Unless the painter specifically undercoats these exposed edges, the routed edges will have fewer coats of paint then the remainder of the door, voiding the warranty and lessening protection of the MDF from the elements. Judging by the current finish, I do not expect the painter to either smooth the finish or apply three or more paint coats to the exposed MDF.

Having the timber beading on the exterior with proper silicon sealing between the bead and the glass should provide a smooth enough finish for water runoff.

That is also what staff from Hume that I have contacted have told me (except the QLD Rep and Sales Manager).