My air con guy brought me a PCB which he got off another system which is encased in such a way that rodents/geckos could not infiltrate it. Obviously, someone has figured out a solution. I will take a photo of it soon and send it to a member to share if appropriate. He didn’t tell me what brand system it was from. I will take a closer look at it and come back, but I hope this topic is still being pursued somewhere out in the ethos!

Okay, here we are less than one year since the PCB was replaced and lo and behold, another gecko incident last night! This is the THIRD PCB to fail due to geckos (original one within 3 months and two subsequent Warranty replacements). Do not, I repeat, DO NOT purchase a Toshiba air conditioner. No design of this inferiority should be allowed in Australia. Is the CHOICE team still pursuing this issue? I haven’t heard a thing lately.

I would like to add that thanks to suggestions in this thread, these are the mitigation efforts we have taken since the last PCB was installed in April 2021:

- Raised the outdoor unit off the ground;

- Kept the leaves and debris swept out;

- Hung a moth ball container at the back;

- Put egg shells filled with tobacco and coffee grounds;

- Applied ant sand along the hoses and around the ground; AND

- SK Air applied some sort of coating in April 2021 that is supposed to deter geckos (a known problem).

Any chemical repellent will need to be replaced regularly - assuming that it is effective in the first place.

I would be screening openings or building a cage for the unit if that was easier. Something like reinforced fly screen or fine weldmesh.

I know that doesn’t address the issue of the product being fit for purpose but how long will that solution take?

That may be possible but airflow is a consideration. Meanwhile, I have photos of a PCB that has been encased in a type of resin to prevent infiltration. Why can’t air conditioner design incorporate this? Would Chris Barnes or someone let me know how to share the photos? Thanks.

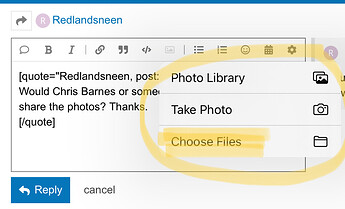

Select the little mountain icon in the reply editing window.

It will bring up an option like this.

You can browse to the folder where your pics are and select which ones you require. Or go to your photo library if that is where they are.

I tend to select one at a time. You can add more to the sane message. Selecting an image in the preview pane should bring up a mini window or tag with the option to size down to 50% or 75% if you feel the image is too big.

Somewhat reduced airflow is better than none.

Was there physical evidence a gecko caused the failure?

Not the air conditioned air flow, but the air circulation around the board itself…which may be why it is not caged up by design. Although that doesn’t explain the design of the sealed PCB I uploaded a picture of.

I guess…there were 3 dead geckos inside the unit, one of which looked a wee bit “fried,” from what I’m told.

Success.

Epoxy encapsulation. It’s been around for as long as there has been plastibond and araldite. 60+ years. The epoxies used for electrical work are special grades to suit the voltages. There are also spray on or dipped coatings that can be built up to provide similar protection

Hi Mark, glad you’re still participating in this discussion. What are the chances that the authorised warranty repair service people would be able to do that to the new PCB during installation?

You could buy and supply it to them to do it.

An example of a spray on one, this one uses a type of conformal and a few coats are advised

https://www.jaycar.com.au/circuit-board-lacquer-spray-can/p/NA1002

And another

https://www.plastidip.net.au/product/let-clear--aero-170gram-62

I have not used the second company so it is purely an example not a recommendation of the product or the business.

Another one that is conformal

Anything is possible.

- Whether the service agent has a suitable workshop and capable employees would need to be considered.

- There are a number of companies that specialise in supplying and or applying coatings. Hence it’s possible to source appropriate expertise independent of the importer and manufacturer.

- The importer manufacturer may be prepared to offer advice or they may object. It’s common for the Aussie end of the supply chain to be disconnected from the OEM, suggesting they are more likely to avoid commitment.

- Some technical knowledge of the product is required in choosing the most appropriate protection and application procedure/method.

A professional designer of the AC electrics/electronics would refer to another specialist for a solution. Do they exist?

EG Encapsulation - Pritchard Electronics

It’s an area outside of my design experience.

Thanks. They told me they automatically apply some sort of spray deterrent, but I’m talking about totally encasing the PCB so nothing can get to it (see photo). Is that what you’re talking about it?

You spray it over the entire PCB to form the barrier, some come in paint ons as well. Spray on allows anyone who can access the PCB to do the job. Dipping by manufacturers is normally done but some are less than adequate or even non existent.

So yes it is a way of encasing the whole PCB in a barrier, the back side can be difficult to access at home so the tech before they put in the new PCB can coat the board for you at their workshop to allow drying time rather than waiting for drying on site.

I use the jaycar purchased one for when I am doing electronic hobby stuff, I use it more as a ‘dewing’ protection than an animal ingress protection, and why I would recommend a few coats of it rather than a single one in the case of avoiding gecko, cockroach, ant, spider, etc damage.

We normally suggest Action Corrosion on our ducted air conditioner installs in Brisbane, we apply it at our factory before we dispatch the unit to the Jobsite. Great product, see video below ![]()

Assuming they are happy to do so, they may also be prepared to recommend a particular product. They will have a supply chain that is backed up with some technical expertise.

What ever product is used it needs to be stable under voltage stress for many years. A little knowledge of the board/s will be important to ensure higher operating temperature components are able to effectively dissipate heat.

The second of your examples has ASTM supported dielectric testing. The third has a list of recommendations in respect of chemical resistance. What ever product is used it’s important to manage the risk of it not performing, or causing another worse problem. I’m risk adverse in this instance and would seek an assurance in writing from the supplier the product is suitable - fit for the exact purpose before using it. Think a fire or electric shock as two possible unintended consequences as worse case scenarios if the product is not appropriate. I’m assuming here the board has 230V or similar mains AC level voltages and load currents.

P.S.

Noted @thehvacdude post. Assume the boards you have coated include mains level voltages?

Welcome @thehvacdude

Thanks for adding your experience.

At this point it’s not known what voltages are found on the Toshiba board, or if it has an coating of some type from the OEM. Does the product you use have a dielectric rating?